EcoGalvanic

company Services

Our Services

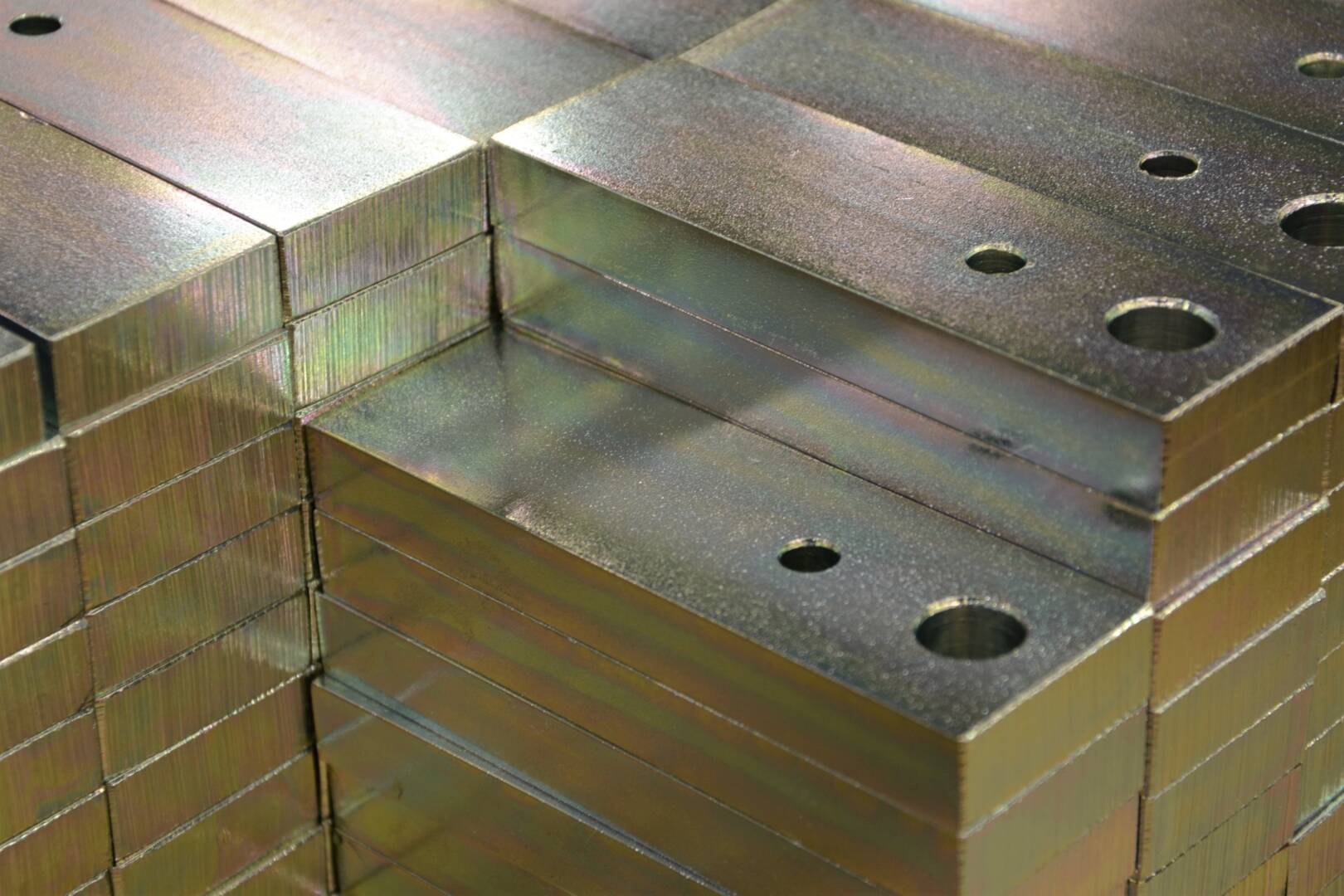

Zinc-nickel

An electrolytic, inorganic, corrosion protective coating system suitable for application on parts which require very high corrosion resistance such as parts for automotive or construction industry.

Corrosion Performance

> 720 h to base metal corrosion according to ISO 9227 (NSS).

Supplemented treatment with sealer increases corrosion protection.

Meets VOLVO, Scania, ISO 4042 standards, etc.

Line description

Automatic barrel line with a capacity 800 kg/hour.

Automatic rack line with a capacity 20 mln. dm2/year.

Characteristics

Nickel content is between 12-16%.

High thermal resistance.

Extremely good corrosion inhibiting properties of the thin layers > 5 microns

Friction controlled with sealer / topcoat.

Meets ELV and RoHS directives.

Drum or rack application.

Appearance

- Black Finish

- Silver Finish

Acid Zinc

Electroplated zinc is the most economical and effective treatment for functional and decorative corrosion protection. It gives very bright and ductile coating. Metal parts can be plated on racks as well as in drums.

Line description

Acid zinc

– rack plating window 2300 mm x 1250 mm x 450 mm

– barrel plating

Properties

Good corrosion protection properties with layers > 8 μm.

Good metal distribution over current density area.

Controlled friction with sealer/topcoat.

Hanging or drum application.

Meets ELV and RoHS directives.

Corrosion performance can be reached by choosing different passivation layers and topcoats.

Appearance

- Blue

- Yellow

- Thick

Corrosion Performance

According to thickness layer and material properties.

Nickel/ Nickel Chrome 3+

Electrolytic decorative NiCr 3+ plating is suitable for interior car parts, furniture and home appliance, etc.

Line description

Rack plating window LxWxH – 2700 mm x 1000 mm x 370 mm

Characteristics

Cr VI-free

Decorative, high reflective glossy surface appearance

Improved mechanical properties

Meets ELV and RoHS directives.

Hanging application.

Appearance

- Nickel

- Nickel Chrome

Corrosion Performance

According to after-treatment applied

Appearance

Grey, porous appearance

- 1

- 2

ecoGalvanic

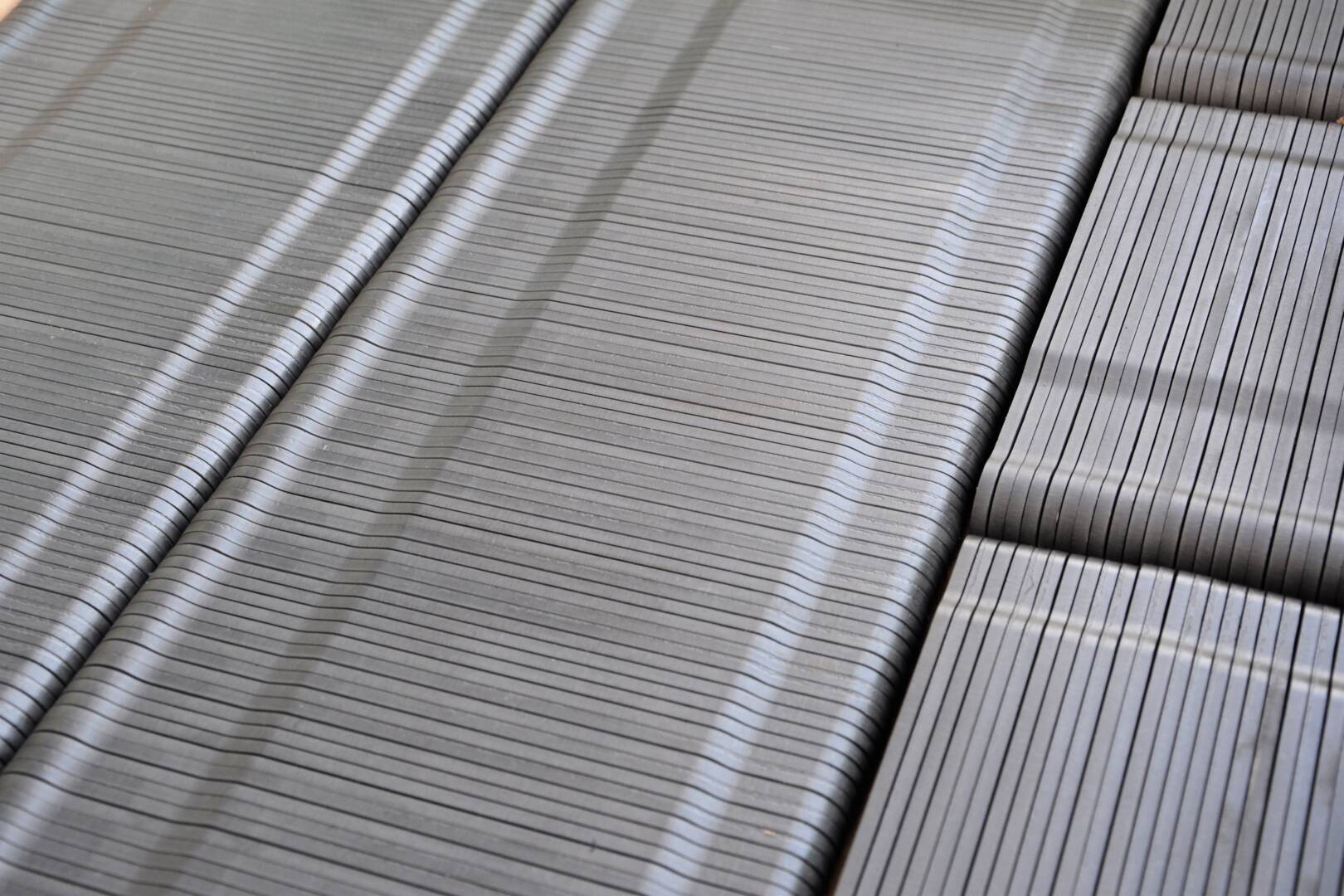

Phosphate

Zn Phosphate pretreatment which is mostly used for parts prior to coating or painting. Phosphatizing increases corrosion protection and improves friction properties of sliding components.